Let’s Demystify 3-D Print Technology

&

How it Impacts the Design Build Community

There is exciting news for all you design lovers out there.

3-D Printing is becoming more accessible, more affordable and faster than ever.

Still not sure how the process works and can’t seem to wrap your head around it?

Check out this video above to give you a visual understand of the process.

Let’s start with the basics.

- 3-D Printing is a 35 year old additive (key word!) manufacturing process that builds material layer upon layer, and is controlled by a computer.

- Currently we can print material using wood, plastic, metal, glass and organic material (food and organs! Yes you heard that right!).

- This is technology that’s going to impact our industry as much as the industrial revolution.

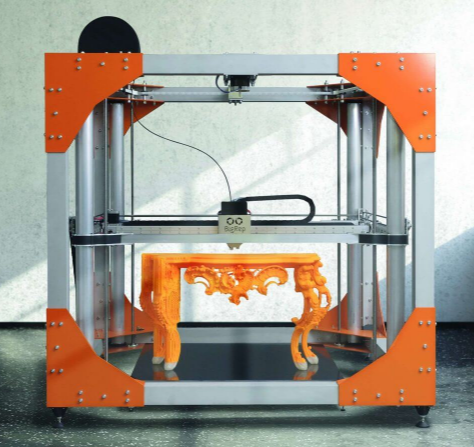

A Rococo table, is being 3-D printed using contemporary materials and colors. A great way to make the old new again.

3-D Design and Printing is here and only getting bigger.

In 1995, it was a $295 Million Dollar Industry.

In 2014, it grew to a 4.1 Billion Dollar Industry.

By 2020, it’s projected to be a 21.3 Billion Dollar Industry.

According to Ben Uglow of Morgan Standley

These are number you can’t ignore.

There are some titans in the industry who are creating innovative pieces of furniture in a way that is forward thinking and environmentally conscious.

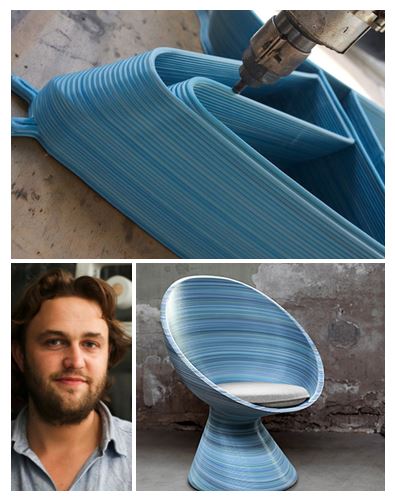

Dirk van der Kooij is printing furniture that is Cradle to Cradle using 100% recycled plastic, printing locally and with less environmental impact. Check out more of his work here.

Bram Geenen has streamlined the process to be more efficient using a thin expensive carbon fiber skin that is printed on top of 3-D material without waste.

Check his work out here.

Lilian van Daal is inspired by nature and Biomimicry. With her designs, she is changing the shape and feel of furniture being built with 3-D printing so that it’s hard where it needs to be (legs for support) and soft in other areas (like the seat and back).

There are Still Challenges

This isn’t a magic box. You need tools or you need help.

- Inexperienced designers will need education or an engineer to build the CAD models to then manipulate and customize designs in scale, proportion, material, etc.

- They haven’t perfected the process of the conception to finished product.

- This is still expensive technology at this phase in the game. Printers run anywhere between $50,000 to $100,000.

How Can You Design Your Own Line?

What’s exciting to me about all this is that there is NO barrier to entry. Currently, if a designer wants to develop their own collection of furniture, they have to work with existing powerful brands who hold the magic key. As 3-D printers become more accessible, designers can soon create their own line whenever they want, or print one-offs. It will be like a Kinko’s for the design build industry. This is nearly impossible with expensive traditional manufacturing. When you design your own piece, it’s highly customizable where you can easily change the color, dimension and entire concept.

Now Watch This!

If you printing furniture blew your mind, check out an entire HOUSE (above).

This home was built in 24 hours and only cost $10,000!

So Where Are We Going?

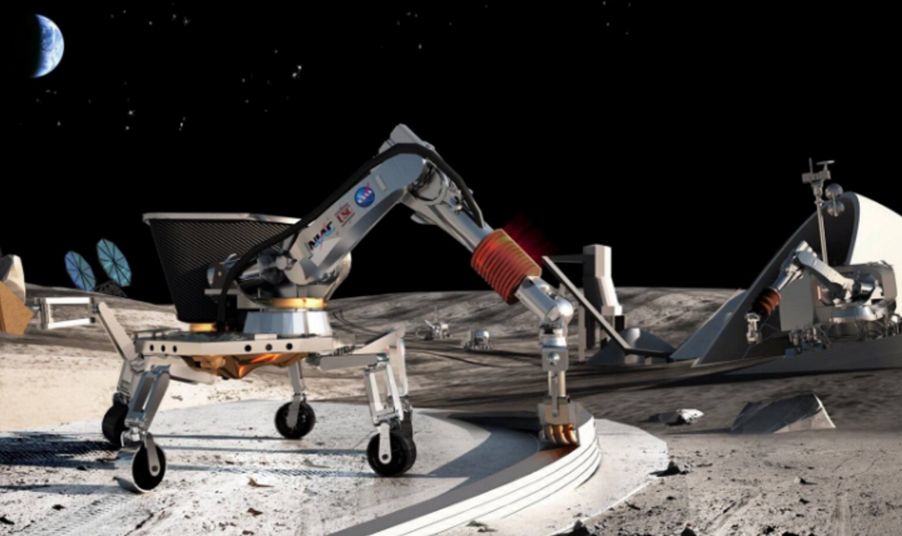

To the moon, Alice!

You heard me. Norman Foster + Partners has completed a project with robotic arms that will be sent to the moon to 3-D print homes made of moon dust!

And now, the sexiest scientist I’ve ever seen, Neri Oxman. Neri is a material scientist at MIT and is printing wearable skin embedded with organisms to help humans survive in interplanetary travel. It’s crazy!

Check out her TED Talk here.

Story of Provenance

If you’ve read this far in my blog, that tells me you’re interested. Great! So now you can participate in the conversation and join the community which is your opportunity to be a part of a new story.

In printing your own designs, you can create an emotional connection and customization in your work to share with your clients about being at the forefront of the industry. That’s quite impressive!

Because of all this, I’ve joined the Board at Print the Future which will be the next wave of printing ideas on demand. We’ve set up a Pop-Up shop in NYC during the month of March 2017 so you can see the printer with your own eyes.

I am incredibly inspired and can’t wait to see what the future holds!